Blogs

Post-shaping deflection measurements

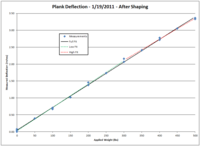

January 20, 2011 - 08:40 — GeoffS After a final sanding I deflected the plank to 500 lbs, then applied the first (and likely final) coat of epoxy. The spring-constant changed almost imperceptibly, from the "raw state" value of 149 lbs/inch to 151 lbs/inch after shaping. Since I'm a geek, I fit the data

After a final sanding I deflected the plank to 500 lbs, then applied the first (and likely final) coat of epoxy. The spring-constant changed almost imperceptibly, from the "raw state" value of 149 lbs/inch to 151 lbs/inch after shaping. Since I'm a geek, I fit the data

- GeoffS's blog

- Login or register to post comments

- Read more

- 5278 reads

Looking for the Runner Mold

January 19, 2011 - 20:32 — the IceMakerI spoke with 4691, somebody has the runner mold, but who?

I'm building a few sets of inserts, and one or two sets will be available this month. will post photos of progress...

4695

- the IceMaker's blog

- Login or register to post comments

- 3076 reads

The plank is off the jig...

January 18, 2011 - 06:59 — GeoffS(actually, it's back on the jig to let the epoxy completely cure...)

I pulled all the clamps off, quickly cleaned off the excess epoxy, and eagerly checked the deflection. It looks pretty good, about 145 lbs/inch so it deflects just under 1 3/4 inches with me on it. I'm guessing it will stiffen up a bit as the glue gets to full cure, and rounding the edges will probably soften it, so it will probably end up very close to this value.

- GeoffS's blog

- 4 comments

- Read more

- 5687 reads

New plank glued up...

January 17, 2011 - 08:37 — GeoffSThe final (and most lengthy) part of the repairing my DN after the crash on Jan. 2nd was to build a new plank.

- GeoffS's blog

- Login or register to post comments

- Read more

- 4695 reads

Light Snow

January 17, 2011 - 03:45 — MMadgeThis is what is covering most of the Bay

- MMadge's blog

- Login or register to post comments

- 2863 reads

Silver Harbour Launch Site

January 17, 2011 - 03:36 — MMadgeLaunch site looking East.By enlarging the picture you can see further out past the launch site is fairly new ice, with very little snow cover.It was only about 3" in thickness,so still needed a little growing.The Temp this week are showing a real cooling trend,so building ice should not be a problem.

- MMadge's blog

- Login or register to post comments

- 2906 reads

Amount of snow in small Harbour

January 17, 2011 - 03:34 — MMadgeThis is how much Snow we got Friday night.It is about 1.5 cm easily sailable in the 10 mph winds today.Nice smooth black ice under the coating of snow.

- MMadge's blog

- Login or register to post comments

- 3007 reads

Where I sailed today

January 17, 2011 - 03:32 — MMadgeLittle harbour to the right of lauch site at Silver Harbuor.About 700 yds long by 500 yds wide.Being I was the only Ice Boat sharing the ice with a couple fisherman and a buddy of mine and given the fact it is a shawllow bay with 6" of ice made for safe sailing.Further out from Silver Harbour the Ice was very smooth with just a light covering of hoar frost.Given the fact it was only 3" thick it was probably sailable but wise by myself not to.

- MMadge's blog

- Login or register to post comments

- 2935 reads

Sleeping Giant

January 17, 2011 - 03:30 — MMadgeFew from Silver Harbor today,looking out towards the Sleeping Giant.there istill some open water about 1.5 miles out.

- MMadge's blog

- Login or register to post comments

- 2899 reads

Hoar Frost

January 17, 2011 - 03:28 — MMadgeThis is snow on main part of Lake

- MMadge's blog

- Login or register to post comments

- 2794 reads

Silver Harbour today

January 17, 2011 - 03:27 — MMadgeLight covering of snow looking out towards Sleeping Giant

- MMadge's blog

- 1 comment

- 2990 reads

help with runners for a Spark (Norsk Kicksled

January 17, 2011 - 00:20 — danaI've a Norsk Kicksled, a Spark, with rusted runner edges. Anyone know where I might get the polyrunners I've read about OR get the blades polished? Thanks!

- dana's blog

- Login or register to post comments

- 3249 reads

we got ads

January 15, 2011 - 02:39 — us5214Hey Everybody,

Google adsense ad test in progress...

The site is only receiving the Public Service Announcements so far. I'm going to give it the 48 hrs google recommends and see if the ads get more targeted.

In these challenging economic times, there is no free lunch.. so hopefully the site can help to pay the hosting costs. (New servers = faster site).

thanks,

jim

- us5214's blog

- 4 comments

- 3369 reads

Lauch Site

January 14, 2011 - 15:13 — MMadgeEnough ice at lauch site to drive on.

- MMadge's blog

- Login or register to post comments

- 3031 reads

More pics from Silver Harbour

January 14, 2011 - 04:20 — MMadgeSilver Harbour looking North.This ice goes on for about 5 miles.

- MMadge's blog

- Login or register to post comments

- 2873 reads